I’m thrilled to have Simon Shiu, Director of HP Labs’ Security Lab, as a guest blogger today. Simon and his team are focused on creating a trustworthy information system environment in the face of challenges such as the growth of organized cybercrime and the rapid adoption of social networking tools and cloud-based services.

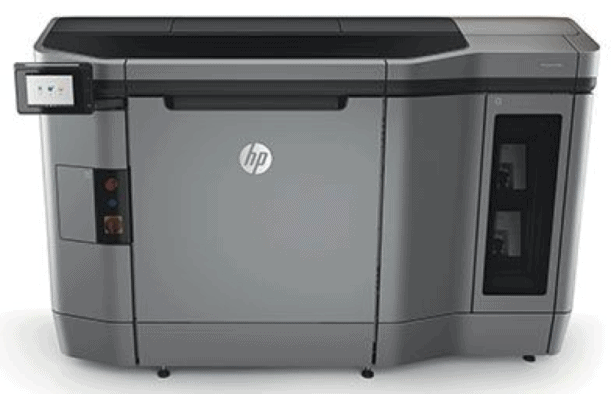

We’re on the cusp of a manufacturing revolution. 3D printing – as Shane has previously written and spoken about – is making the translation of digital ideas into physical products a reality. From hobbyists to manufacturing giants, the vision of the next 10 years is that additive manufacturing – or manufacturing 4.0 – will be at work at all scales and across the world, producing an almost infinite range of products. From 3D-printed human body and airplane parts to the inner workings of 3d printers themselves, we will be relying on a whole new suite of technologies to make our Blended Reality-infused world.

This revolution is transforming the entire manufacturing process into a digital one, where digital designs are distributed in cyberspace to the place where the final product is needed, and only then digitally printed with voxel-level precision.

The HP Multi Jet Fusion multi-agent process transforms part properties at the voxel level, providing unprecedented control today.

This digitization of manufacturing is exciting and transformative, but it also brings some interesting and thorny security challenges. 3D printing is not just about a new machine, it’s about a new digital ecosystem that stretches from the first design idea to the end of a printed product’s life. We are working to understand and design security into each stage of that process, creating an end-to-end approach.

The security challenges of digital manufacturing are myriad. In addition to the largely economic consequences of cyber-attacks that we are used to today, attacks in a 3D ecosystem could have serious consequences for the integrity and safety of physical products. For example, 3D designs moving through such an ecosystem will be vulnerable to voxel-level manipulation or changes in the material properties. This means there will be particular pressure to guarantee quality and reliability of 3D digital workflows.

Requirements for information assurance, accountability and audit will drive new business models and ways of working for all participants in a 3D printing workflow. We need to ensure that each of the customer, designer, 3D print service or healthcare provider are able to demonstrate and defend their work. This could include the quality of production and its confidentiality, through a digital distributed manufacturing chain.

In HP’s Bristol-based Security Lab, the team is working on security innovation.

Of course, the story doesn’t end with the printing of a 3D part. 3D printed objects will need to be mapped to their digital history to enable the trust to move with the product. This will provide the key assurances needed to verifiably connect the digital and physical parts of the ecosystem for a safe Blended Reality world.